General Plastics

From Concept to Reality™ Your positive outcome is our singular goal.

For three decades, the General Plastics’ team has provided comprehensive assistance

for the Original Equipment (OEM) and Point of Purchase (POP) markets.

Utilizing innovative approaches to sheet plastic fabrication.

Thermoformed plastics are ideally suited for mass transit, consumer products, packaging, retail and display, sports and leisure, electronics, and industrial applications.

General Plastics utilizes innovative approaches to sheet plastic fabrication, such as: Thermoforming, Vacuum Forming, Pressure forming, Fabrication and Turnkey assembly.

Our clients have enjoyed a broad spectrum of successes with challenging quality, lead-time and cost-containment objectives. Whether your project involves a single part or multiple components we can offer insights to assist with a design from

Concept to Reality™

Additional Benefits:

- concept realization

- process design

- tooling prototype and production

- part production on state-of-the-art equipment

- CNC and robotic routing

- quality and process management

- assembly and secondary operations

- inventory control

- turnkey solutions

Excellent Price/Value Ratio

Superior Project Management

Award-Winning Quality

Your Single Source Supplier

Strategically integrated value added operation including:

- heat bending

- hot stamping

- solvent and adhesive welding

- riveting

- edge treating

- painting

- special design features (bosses, ribs, and special fastening devices)

These can significantly shorten your production lead times by eliminating the costly and time-consuming process of sourcing multiple suppliers.

Your Total Turnkey Resource

Customized Shipment Solutions

Advantages of Converting Metal to Thermoformed Plastics

Upgrading to thermoforming from metal has many advantages that provide the aesthetics required in today’s market at minimal cost. There are several benefits for converting metal to a thermoformed part. The four most important (benefits) are: Cost Weight Design...

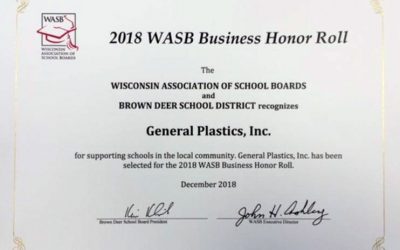

General Plastics is on the 2018 WASB Business Honor Roll for supporting schools in the local community!

General Plastics, Inc.: Community Involvement

General Plastics, Inc. is not only located in Milwaukee, Wisconsin, but it is a valuable member of the community, willing to work with others to solve concerns by applying what the company knows best – conceiving problem-solving solutions and producing solutions...

Follow Us!